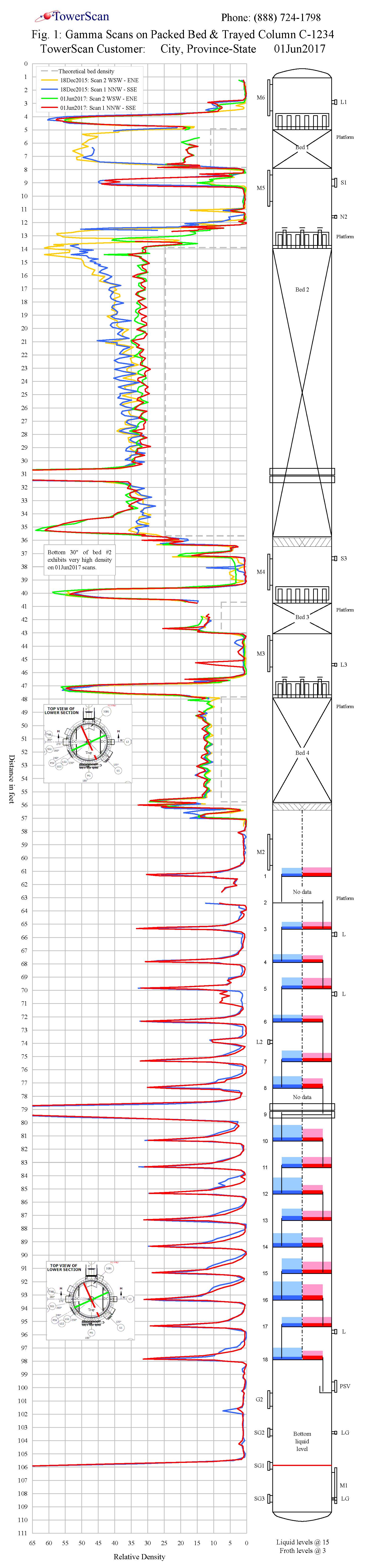

Solutions Today Plan for Tomorrow

With any process column, problems can, and will, arise over time. At TowerScan, we pride ourselves on keeping process units operational by helping to quickly and efficiently identify problems when they occur. Using a range of techniques, we can help you plan for your next outage and spot issues with your distillation towers and other process equipment that might cause downtime in the future.